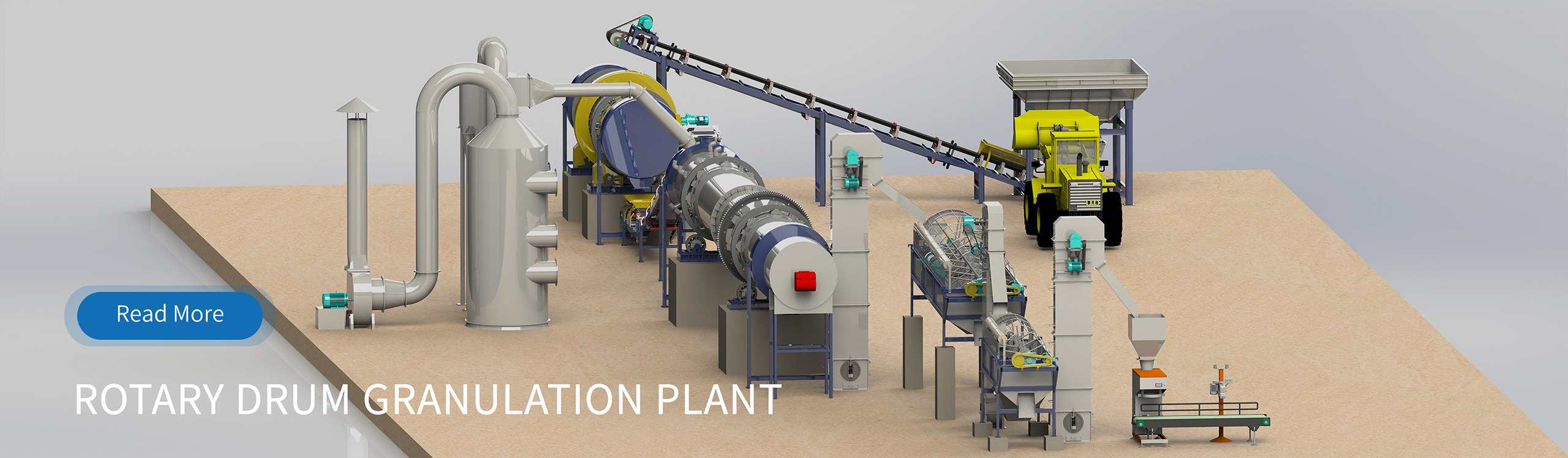

Description:

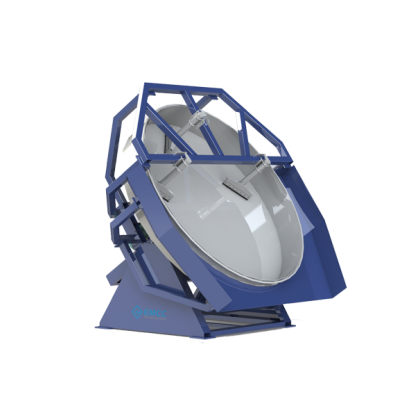

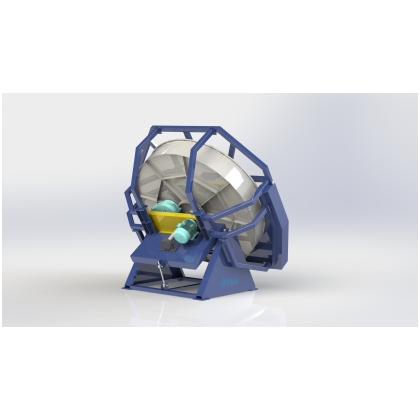

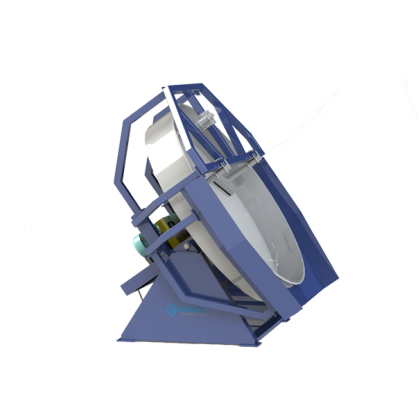

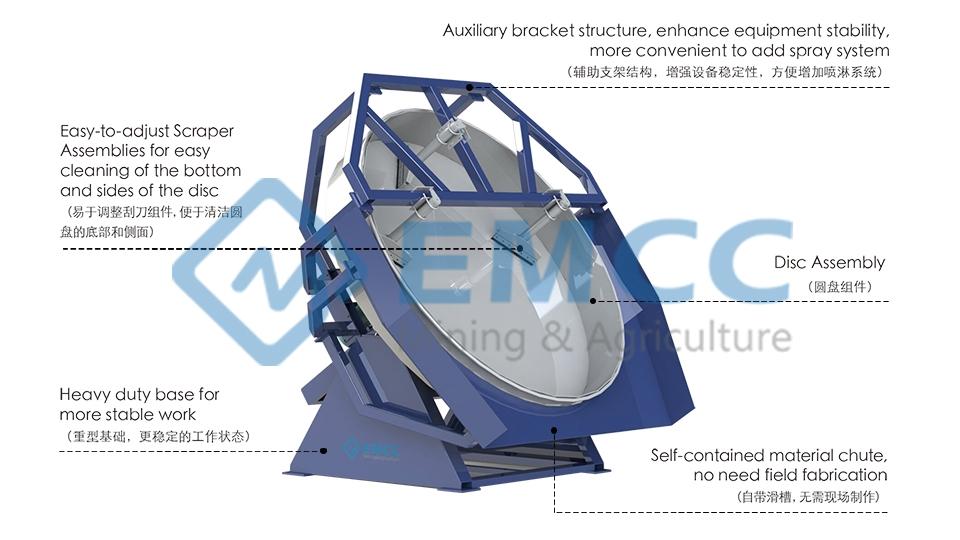

EMCC’s Disc Pelletizers (also known as pan pelletizers) are the equipment of choice for converting powdered materials into uniform, round pellets.Disc pelletizers utilize a non-pressure (tumble growth) approach to agglomeration and work by tumbling material on a rotating disc, with a binding agent and feedstock being continuously added. The binding agent causes the fines (or seed pellets, when utilizing a pre-conditioning step) to become tacky and pick up additional fines as the material tumbles against itself. This causes a “growing” action referred to as coalescence. Once pellets have reached the desired size, they exit the rotating disc via centrifugal force.

DEVICE DETAILS

Disc fertilizer granulator emerges with the development of fertilizer production.It is appropriate for granulating round fertilizer particles for compound or organic fertilizer for convenient transportation and storage.To produce nutritionally balanced fertilizer particles, the proper granulating machine is your top decision. We are professional fertilizer plant and will offer you practical guidance in fertilizer granulating. You can also spread atomizing NPK to increase nutritions in organic fertilizers during granulating.

APPLICATIONS & MATERIALS

EMCC’s Disc Pelletizers can agglomerate everything from fine, dry feed materials, all the way to wet, sludge-like materials. Some of the most common applications for pelletizers include:

| -Chemical Powders | -Limestone / Gypsum | -Fertilizers |

| -Coal fines | -Cement / Lime Kiln Dust | -Flyash |

| -Filter / Centrifuge Cake | -Minerals and Ores | -Vibrating Sludges |

| -Pond tailings | -EAF Dust |

TECHNICAL PARAMETERS

| Model | Disc diameter (mm) | Disc depth(mm) | Working speed (r/min) | Capacity (t/h) | Power (kw) | Dimension(mm) |

| ZL-500 | 500 | 200 | 32 | 0.02-0.05 | 0.55 | 650x600x800 |

| ZL-600 | 600 | 280 | 33.5 | 0.05-0.1 | 0.75 | 800x700x950 |

| ZL-800 | 800 | 200 | 21 | 0.1-0.2 | 1.5 | 900x1000x1100 |

| ZL-1000 | 1000 | 250 | 21 | 0.2-0.3 | 1.5 | 1200x950x1300 |

| ZL-1200 | 1200 | 250 | 21 | 0.3-0.5 | 1.5 | 1200x1470x1700 |

| ZL-1500 | 1500 | 300 | 21 | 0.5-0.8 | 3 | 1760x1500x1950 |

| ZL-1800 | 1800 | 300 | 21 | 0.8-1.2 | 3 | 2060x1650x2250 |

| ZL-2000 | 2000 | 350 | 21 | 1.2-1.5 | 4 | 2260x1650x2250 |

| ZL-2500 | 2500 | 450 | 14 | 1.5-2.0 | 7.5 | 2900x2000x2750 |

| ZL-2800 | 2800 | 450 | 14 | 2-3 | 11 | 3200x2200x3000 |

| ZL-3000 | 3000 | 450 | 14 | 2-4 | 11 | 3400x2400x3100 |

| ZL-3600 | 3600 | 450 | 13 | 4-6 | 18.5 | 4100x2900x3800 |

ADVANTAGE

1. Arc structure ensures high granulating rate of 93%.

2. Novel and rational structure,light weight. Flexible granulating position.

3. Adjustable angle of large discs because of the pads.

4. Unique unpowered knives lowers down power consumption.

5. Large discs consists of disc body and disc joints. The disc joints can be accomodated upwards and downwards.

6. New dregging design and good granulating effects. Uniform granulators and most of the particles’ diameter is 3-5mm.

7. High working efficiency. It finishes disc granules at one stroke.

8. Simple operation, convenient maintenance and stable performance.

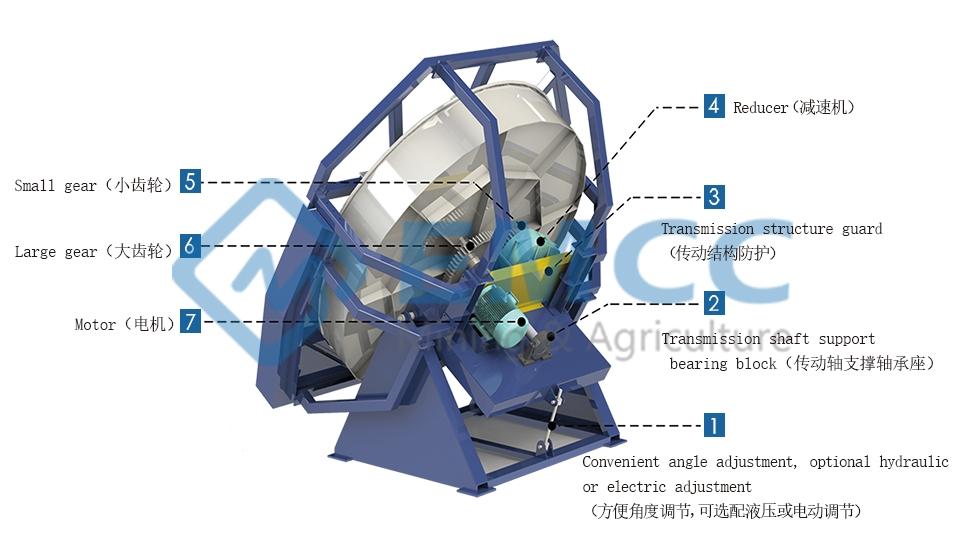

PRINCIPLE

Various dry powder materials are added from the top of the equipment, then being degassed, compressed and transported to arc shaped notch of those two rolls which are doing reversed rotation at a constant speed. Materials are condensed in the disc, reducing the stress-tolerant of materials which naturally separate with each other with the aid of gravity and surface tension.

VIDEO